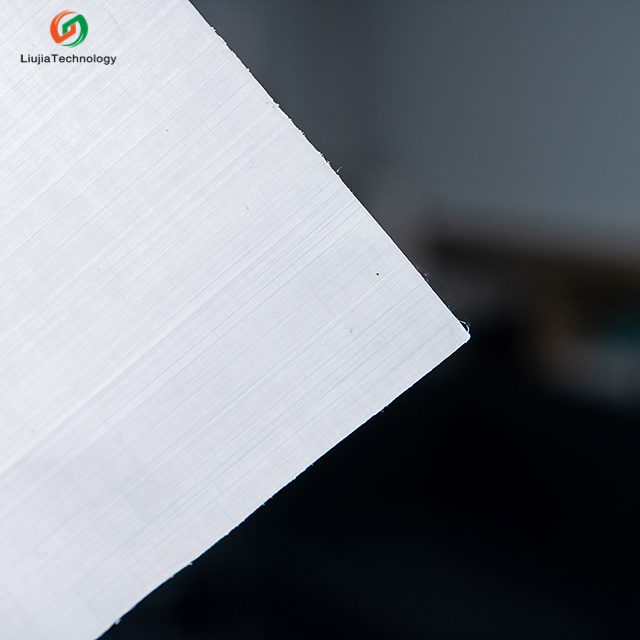

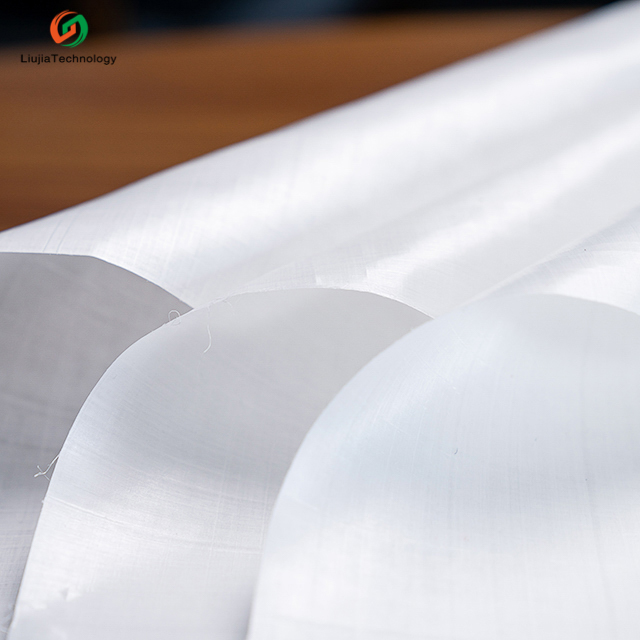

Continuous UD Weft-free Cloth Production Line – Efficient and Reliable Solution

Overview

The company independently builds a complete set of UD production lines for long-term experiments, from single chip to multi-layer lamination. It is the only specialized company that continuously adjusts the structural accuracy of equipment and product quality through experiments to meet customer needs. The company is also committed to long-term research on process and technology, and has rich experience in producing UD fabrics with different specifications and surface densities. During the cooperation process, we can also provide customer support to avoid customers' exploration in the early stage.

Application

It is mainly used in the field of soft bulletproof. It is thin, soft and has excellent wearing comfort. It is light in weight and has good protective effect against shooting threats in various environments. The product is widely used in special protective materials, such as soft bulletproof vests and lightweight bulletproof vests. High-Performance bulletproof helmets, lightweight bulletproof armor plate, anti-stab and anti-cut clothing linings etc.

Main Parameters

| Design width | 1200mm ---- 1600mm |

| Production line speed | 1-7m / min |

| Mechanical speed | 1-10m / min |

| Area density | 35g / ㎡-100g / ㎡ |

| Designed spindle position | 1296 spindles |

| UD continuous line equipment footprint | 36m × 6m |

| Hot press vulcanization equipment area | 17m × 7m |

| Cutting and bonding area | 14m * 3m |

| Storage area | 200m² |

| Suggested production area | ≧ 800 m² (one ud continuous line) |

| Production staff (recommended staff per class, skilled workers, excluding management staff): | |

| One production line | UD continuous line 3 people (2 operators, 1 craftsman) |

| Two production lines | UD continuous line 5 people (4 operators, 1 craftsman) |

| Personnel needed for cutting and bonding device | 2 people |

| Personnel required for vulcanization and hot pressing | 2 |

Capacity Calculation

Theoretical capacity calculation (calculated based on area density 40g/㎡, speed 7m/min)

Theoretical annual output of 1200mm width: 160 tons.

Theoretical annual output of 1600mm width: 215 tons.

Equipment List

Serial number name specifications quantity remarks

1、Bobbin rack with 3 rows*432 spindles; double-sided 6-layer 1 set can be customized

2、Partitions, 6 layers; ceramic yarn guide; 1 set of adjustable layer spacing

3、Warping machine fixed yarn splitting reels 1 set can be customized

4、Front tractor axle type; mechanical speed 1-10m/min 1 set

5、Large roller equipment, including a coating, gluing and drying system

6、Rear tractor bridge type; mechanical speed 1-10m/min 1 set

7、Rewinder width 1.7m, automatic cutting 1 set

8、Cutting and bonding equipment includes: automatic rail cutting knife, hot press bonding machine, and automatic rewinding. 1 set

9、Hot pressing vulcanization equipment (sold separately) including: rewinding and unwinding structure, 1 set of hot pressing host

Power Consumption

Continuous UD weftless fabric power consumption: 600-700kw/ton of weftless fabric (excluding hot pressing).

Engineers able to provide overseas installation, testing and training. Factory layout design, assembly, installation and commissioning, start-up and local team training are provided free of charge.

• Prompt delivery and flexible payment terms

• Welcome strategic partners

• Professional team with strong technical and R&D knowledge to develop advanced food equipment

• Save labor costs and increase production capacity.

Video

FAQ

Q1.Are you manufacturer or trading company?

A1:We are manufacturer and trading company.

Q2.Can you make OEM or ODM service?

A2:Yes.OEM service accepted.Own designer team also welcome to ODM products.

Q3.Can I get samples?

A3:Yes,free samples available if we have stock.

Q4.How about the delivery?

A4:3-20 days after order confirm,depend on quantity.

Q5.How long is the sample cycle? Is it charged?

A5: After the design confirmed, we will make the sample at first time,normally 3-5days,and then we will send it to you,we will send the sample for free if we have stock.,but the sample express cost should be paid by your company.