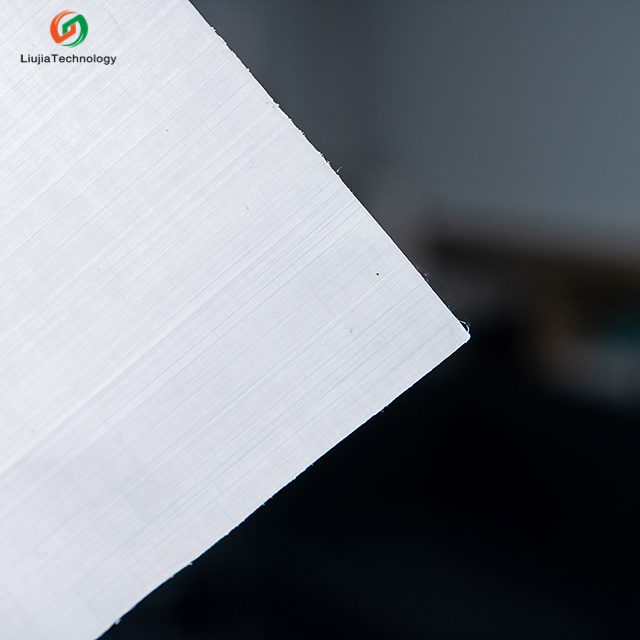

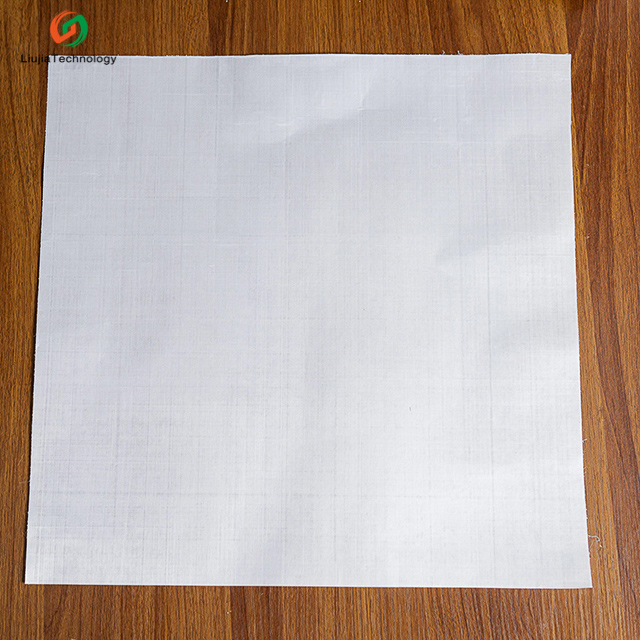

High strength UHMWPE fabric bullet proof materials

Description

The three major high-performance fibers in the world today are: aramid fiber, carbon fiber, and ultra-high molecular weight polyethylene fiber. At present, aramid fiber is only produced in small quantities in China due to technical problems; carbon fiber is still in the test and primary production stage, and the product can only be used in resistant Since the breakthrough of key production technology in 1994, ultra-high molecular weight polyethylene fibers have formed a number of industrialized production bases of ultra-high molecular weight polyethylene fibers.

Specification

| Hard weft free cloth | ||||||||

|

brand |

The raw materials |

type |

The surface density (g/m squared) |

width (m) |

The length of the (m) |

Product features |

Bullet-proof performance |

|

|

Protection level |

Surface density (kg/m²) |

|||||||

|

EH131 |

UHMWPE fiber |

2UD |

120 + 10 |

1.2/1.6 |

200 | Excellent bulletproof performance, good rigidity, light weight |

NIJ Ⅲ (M80) |

13.5 (Platen) |

|

GA141 level 3 |

5.4 (Pressure plate) |

|||||||

|

AH101 |

Aramid fibers |

4UD |

240 + 10 |

1.2/1.6 |

100 | Excellent bulletproof performance and light weight |

GA141 level 3 |

5.56 (Press plate) |

Characteristics

Advantage

1.light texture

The density of UHMWPE is only 0.97-0.98g/cm3, and it can float on the water.

2.Excellent mechanical properties

The specific strength is more than ten times that of steel wire of the same section

·Specific modulus is second only to special carbon fiber

Low elongation at break, outstanding impact and cut resistance

·High wear resistance and self-lubricating

Fatigue performance is the strongest among existing fibers and has a long service life

3.low water absorption

Drying is generally not required before processing

4.Strong weather resistance

It has excellent anti-ultraviolet ability. After 1500h of sun exposure, the strength is still more than 80% preserved. It can shield radiation, so it can be used as a shielding plate for nuclear power plants

5.Hygienic and non-toxic

Can be used in contact with food and drugs

Disadvantage

1.poor heat resistance

The melting point of ordinary polyethylene is roughly the same as that of ordinary polyethylene, which is about 140 °C.

2.High processing difficulty

Ultra-high molecular weight polyethylene has extremely poor fluidity and a melt index of almost 0, requiring special equipment for processing.

3.Low stiffness and hardness.

But this shortcoming can be improved by modification