-

Continuous UD Weft-free Cloth Production Line – Efficient and Reliable Solution

Upgrade your production line with our high-performance Continuous UD Weft-free Cloth Production Line. Increase efficiency and output with cutting-edge technology.

-

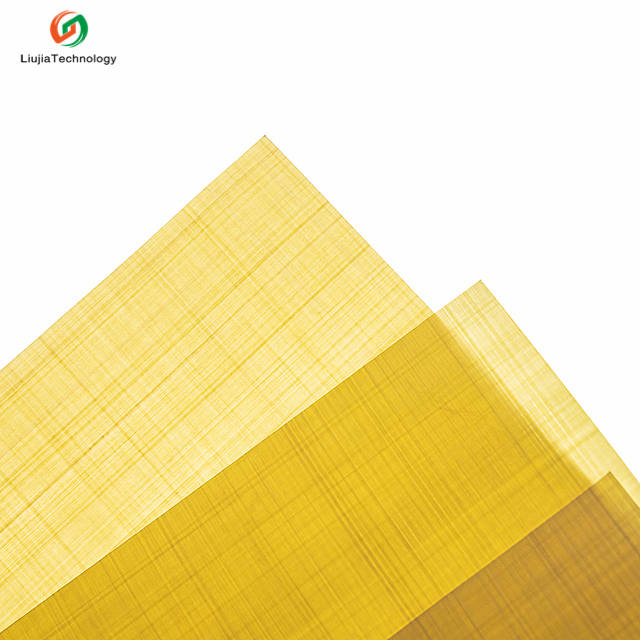

Aramid Fiber custom bulletproof military

The full name of AF is “aramid fiber”, which is a new type of high-tech synthetic fiber with excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, and light weight. Its strength is 5 to 6 times that of steel wire, its modulus is 2 to 3 times that of steel wire or glass fiber, its toughness is 2 times that of steel wire, and its weight is only about 1/5 of that of steel wire. Decomposes, does not melt. It has good insulation and anti-aging properties and has a long life cycle. The discovery of aramid is considered to be a very important historical process in the material industry.

-

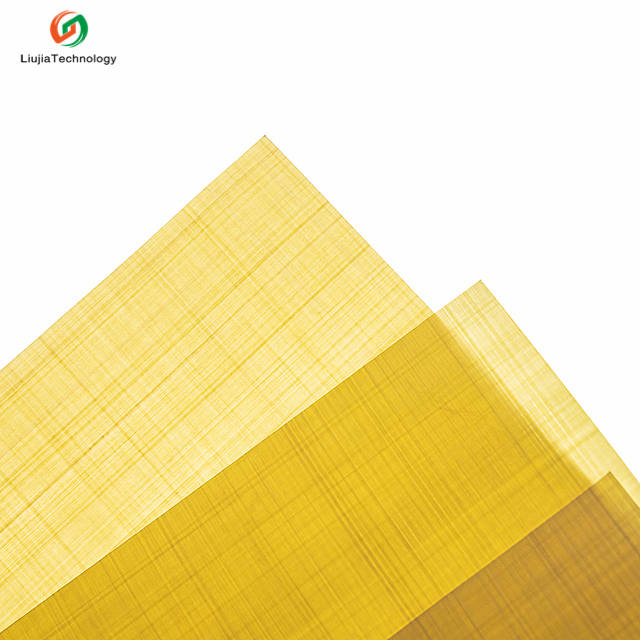

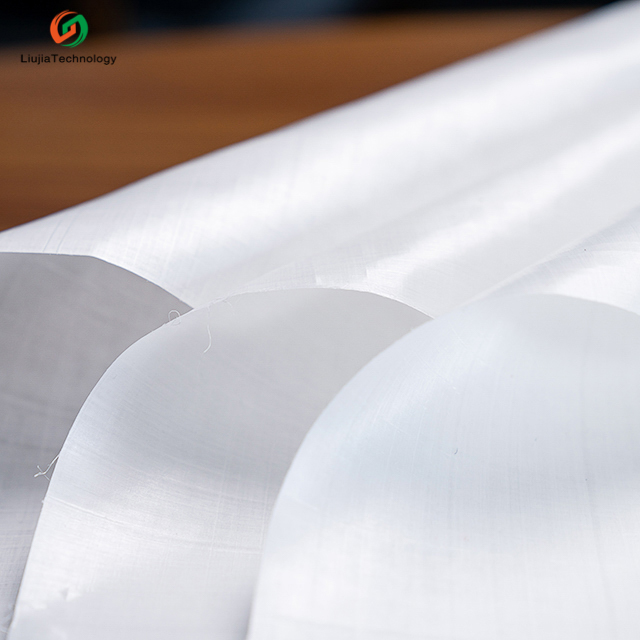

Unidirectional ballistic PE film UHMWPE UD fabric

This UHMWPE UD fabric can be used to produce all kind of bullet proof products like bullet proof vest, bullet proof helmet, bulletproof shield, bullet proof car, bullet proof door, etc. Can reach highest NIJ IIIA.44 bullet proof protection level.

-

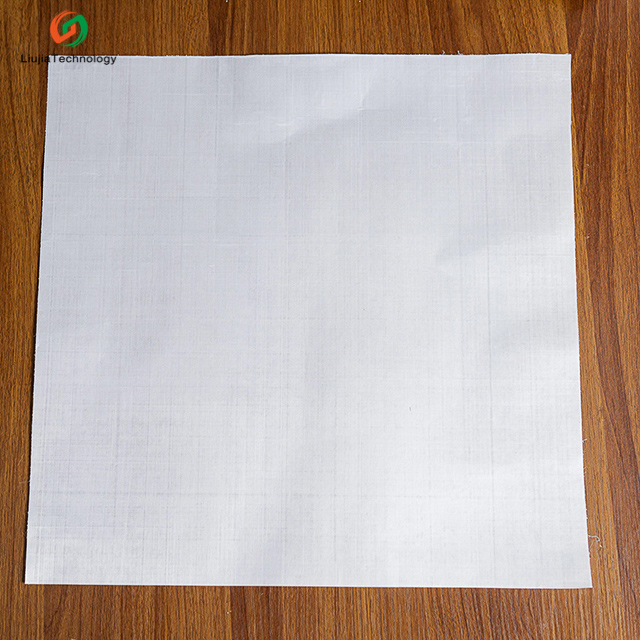

Cost-effective and high quantity UHMWPE UD fabric

Main properties of UHMWPE:

Excellent strength to weight ratio

High wear resistance

low specific gravity

UV resistant

Chemically inert (except for strong oxidizing acids)

-

Popular New Producing Fireproof Uhmwpe Bulletproof Ud Fabric

Ultra-high molecular weight polyethylene (UHMWPE) is polyethylene with a molecular weight of 1 million to 5 million. The molecular weight of ordinary polyethylene ranges from hundreds of thousands to hundreds of thousands.

-

High strength UHMWPE fabric bullet proof materials

UHMWPE UD fabric can promptly distribute energy of a projectile on a large area so as to reduce depth of concavity of materials so that nonpenetration injury can be therefore reduced. Besides, this fabric can absorb shock and block smashed projectiles to prevent secondary injury.

-

Hard bullet-proof material Classical lightweight army used

Using high-strength and high-modulus ultra-high molecular weight polyethylene fibers and aramid as raw materials, it has excellent ballistic resistance and good sag resistance.

-

custom bulletproof NIJ IIIA UHMWPE UD fabric

UHMWPE is a premium Polyethylene with a molecular weight of 9 Mio. g/mol. It has higher wear resistance, mechanical strength and impact resistance than regular UHMWPE materials, which makes it suitable for a large number of industrial applications with higher load limits. Its very good sliding properties make our UHMWPE the ideal material for applications in which the frictional resistance of surfaces should be kept as low as possible. These include, for example, lightweight body armor, bulletproof stab-proof clothing, building protective armor, explosion-proof facilities, etc.

-

High quality bulletproof UHMWPE UD fabric

UHMWPE fiber is currently the fiber with the highest specific strength and specific modulus in the world, with ultra-high strength, ultra-high modulus, low density, abrasion resistance, low temperature resistance, UV resistance, shielding resistance, good flexibility, It has many excellent properties such as high impact energy absorption and resistance to strong acid, alkali, chemical corrosion, etc., and is widely used in military equipment, marine industry, safety protection, sports equipment and other fields.

-

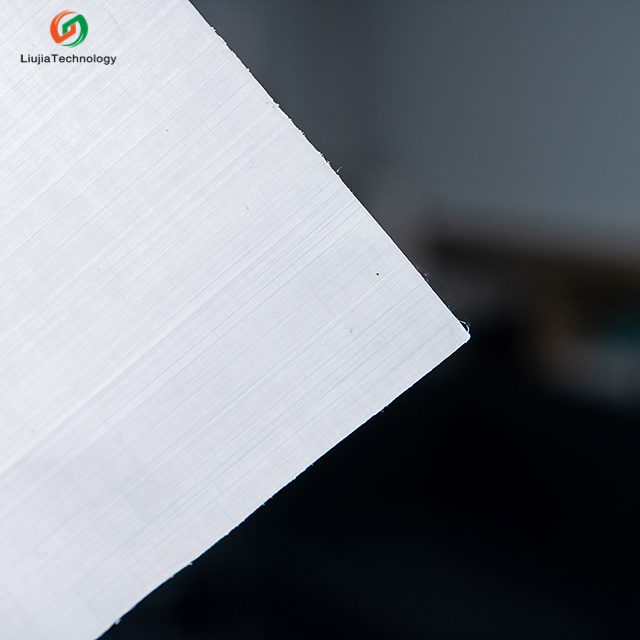

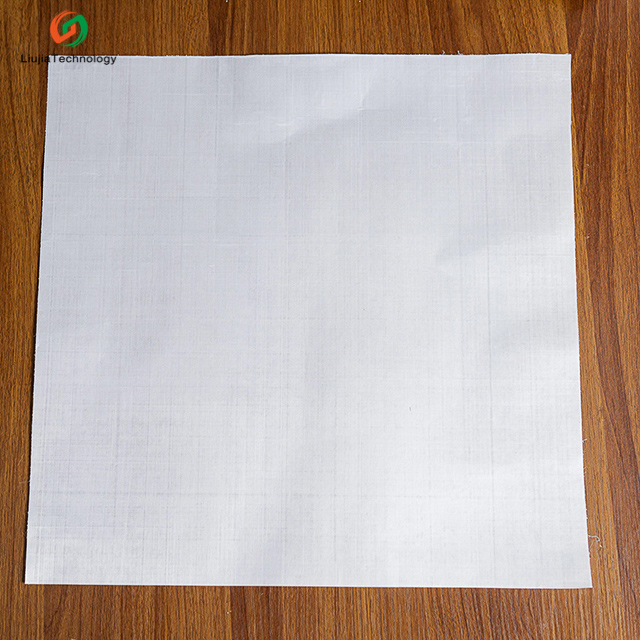

Military quality Blletproof UHMWPE Material

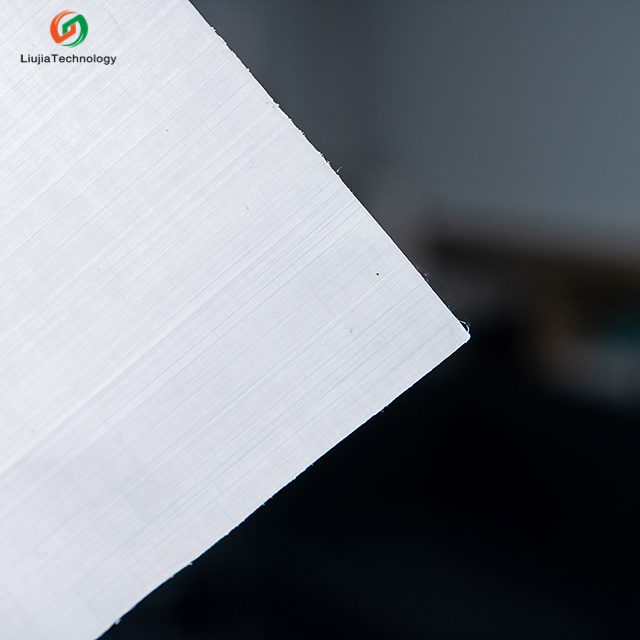

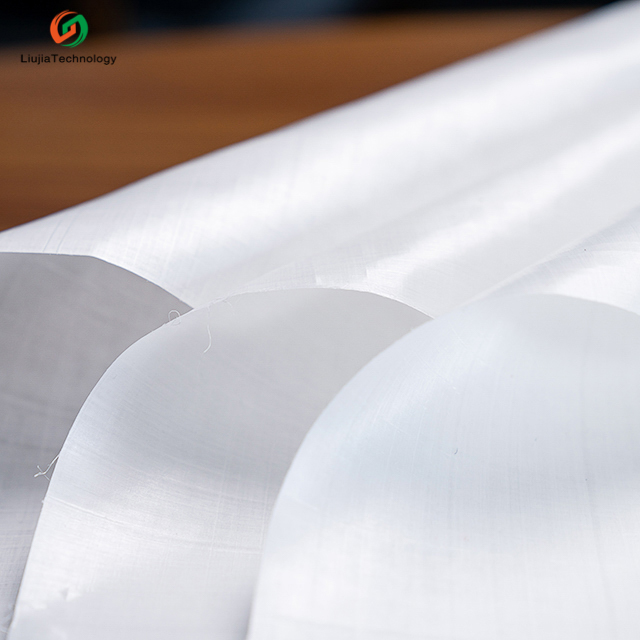

We are offering Bulletproof Fabric (UD Sheet) which is consisted of two plies of unidirectional fiber which cross-plied by 90 degrees e+ach other with special adhesive and certain technology. The outward appearance is white textile fiber thin slice.

-

High Grade White Tactical Vest Material Pe Ud Bulletproof Fabric

UHMWPE fiber, together with carbon fiber and aramid fiber, is known as the world’s three major high-tech fibers. In view of its light weight, high strength and high specific energy absorption, it has gradually replaced aramid fiber and has become the first choice in the field of individual bulletproof fiber.

-

Classical lightweight military army used Soft bulletproof material

Soft bulletproof material —– high-strength and high-modulus ultra-high molecular weight polyethylene fiber and aramid as raw materials have excellent ballistic resistance, good flexibility, and low areal density